|

|

|

|

| SCDnezzy2 - Vision 2025 at London Offshore Wind Energy 2017 |

|

|

|

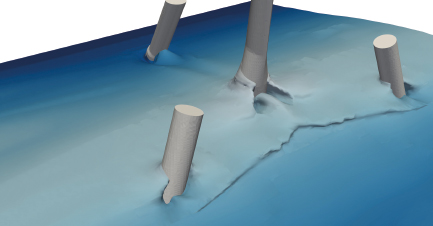

| After several months of an internal study of further improvements for reducing the cost of energy, we are sure that the twin rotor concept with the proven SCD Technology and the innovative nezzy foundation is the perfect solution for increasing power rating, energy yield and economic efficiency. A combination of two proven wind turbines on one foundation,

self-aligning with the changing wind direction, allows wind resources to be utilized more efficiently without any shading and energy loss. The two-bladed rotors are counter-rotating to balance the |

|

Coriolis forces on the system. The two rotors are spaced some meters apart between the tips and work at a angular phase shift of 90° so that no interference influences the turbine wakes.

The use of wind turbines that are already developed will lower the development cost and the time to market. In the past, the rotor size per installed unit increased resulting in a significant rise in the development and logistics cost. Additionally the installation of large wind turbines became

more complex due to |

|

increased hub height. Another very important fact for a twin rotor in the SCDnezzy configuration is a comparison of the mass moment over the water line as a factor for the floating foundation costs. Based on the same energy yield (E) the mass exponent for one large wind turbine is 2.8 compared to two smaller wind turbines with half the power capacity. And the hub height must be approx.

1.4 times higher than for the smaller turbine. Based on the foundation design an increased mass and hub height result in a 1.55 times higher mass moment at the water surface. |

|

|

|

|

|

|

|

|

| After final assembly - inspirations for future improvements |

|

|

|

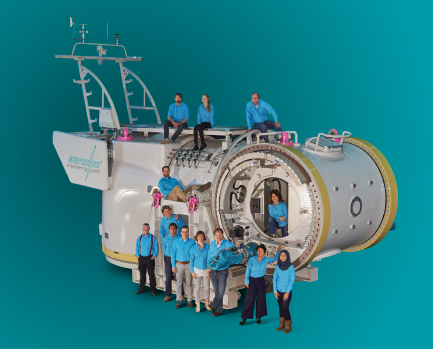

A very important step for aerodyn engineering was the signing of a hardware delivery contract

for a 3.0 MW SCD turbine for a Japanese floating demonstration project in the south west of Japan near the city of Kitakyushu. Due to the high requirements the turbine had to be completely redesigned. After this was

finished, aerodyn signed contracts with the component suppliers and other project partners in the first half of 2016 and started the assembly at the Nobiskrug shipyard in Rendsburg in January 2017. The whole team was

involved in the assembly process. This was the first time that this turbine type was produced and assembled completely in Germany. By the end of March the assembly was finished and a lot of lessons were learned for the

next generation. The installation in Japan will take place in spring 2018. |

|

|

|

|

|

|

|

|

| Successful test of SCD 3.0 MW at CWD in Aachen |

|

| After the pre-commissioning in Rendsburg, the complete nacelle, hub, inverter and transformer container was

transported to CWD (Center for Wind Power Drives) at RWTH Aachen University in Germany. The complete nacelle, including the drive train, was subjected to various mechanical, electrical and dynamic |

|

load tests at this dedicated testing facility. For several days, a number of tests including full torque, overload torque as

well as shear and bending loads were conducted. Also a full programme of dynamic electrical tests like low voltage ride through (LVRT) and frequency ride through (FRT) were performed with great success. A |

|

24-hour full-load test showed the temperature behaviour of all components. After the load tests, the gearbox was inspected by endoscopy,

and tooth contact patterns and the appearance of the other components were found to be in line with the requirements and predictions. |

|

|

|

|

|

|

|

|

|

|

| Further R+D work on SCDnezzy aerodynamics and hydrodynamics |

|

|

|

During our comprehensive research and development works on our SCD and nezzy technology we have gained a great deal of knowledge about the

optimum design of the whole complex system. The floating behaviour, structural design, production technologies, assembly and service aspects like cooling and lubrication have been evaluated based on this knowledge. At the moment, we are working on CFD calculation

of the influence of water currents and air flow on the SCDnezzy turbine for further optimisation. |

|

|

|

|

|

|

|

|

| Lifetime achievement award at WindEnergy Hamburg 2016 |

|

| During WindEnergy Hamburg 2016, the German Renewables Award was presented for tireless efforts towards the success of the energy transition. A jury of eight professionals in the renewable energies sector had selected the three winners. Sönke Siegfriedsen won the “Lifetime Wind Energy” award for his unprecedented

global contribution to developing wind energy technology. Dr. Bernhard Richter as laudatory said: |

|

“Siegfriedsen is a pioneer in the wind energy sector and founder of the Rendsburg-based aerodyn engineering. The inventor can look back on an unrivalled success story featuring 50 patent families and the development of 27 different wind turbine systems operating with some 45,000 turbines worldwide. Today, he focuses on floating offshore facilities

with only two rotor blades to bring down the cost energy significantly”. |

|

|

|

|

|

|

|

|

|

|

| Conference and Trade Fair in London |

|

| To promote our trendsetting technology we will have a booth at the important offshore fair in London from 6 to 8 June 2017. We would very pleased if you visit us there for further in-depth discussions. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

You can unsubscribe this newsletter at any time here. |

|

|

|

www.aerodyn-engineering.com · © aerodyn engineering gmbh |

|

|